Quality Built In — Every Step. Every Product. Every Time.

Our Quality Management system is designed to give you precise control over your product and process monitoring. Every detail becomes traceable and measurable, ensuring clarity and professionalism in all your operations.

Connected Modules.

Undefined Growth

Each module works seamlessly with the rest — giving you one connected platform to manage your entire business.

Browse all features

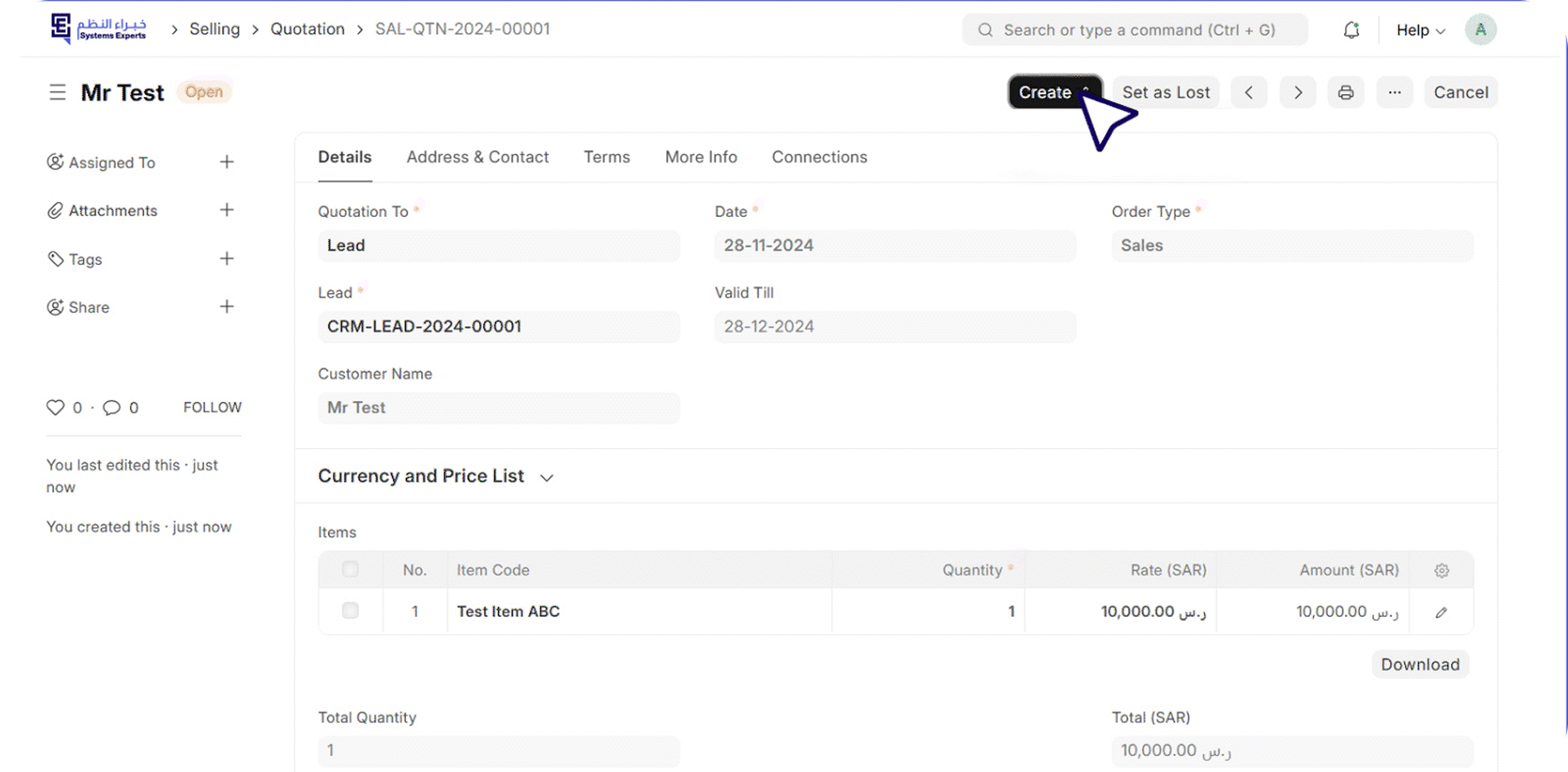

Sales & Engagement Analytics

Monitor pipeline health, opportunity values, and engagement rates from one dashboard.

Lead Capture via Web Forms

Integrate custom website forms to automatically create leads within the system.

Everything You Should Know About Quality

The Quality module empowers your business to plan inspections, perform rigorous quality checks on materials and products, and manage non-conformances — all seamlessly integrated across your operations.

Yes. Customize quality plans with specific parameters and acceptance thresholds tailored to each product, ensuring precise control over standards.

Absolutely. Inspection templates can be triggered automatically when goods arrive, speeding up quality assurance without manual delays.

Yes. Initiate inspections during or after production stages to guarantee your final products meet the highest quality benchmarks.

Through intuitive forms capturing measurements, pass/fail status, detailed notes, and attachments like photos — making audits and reviews effortless.

Non-conforming items are flagged instantly, triggering corrective actions such as rework, rejection, or other workflows based on your quality policies.

Yes. Log complaints by product or batch, perform root cause analysis, and track corrective measures to enhance customer satisfaction and product reliability.

Yes. Generate detailed reports on acceptance rates, rejection trends, supplier inspection stats, and key Quality Performance Indicators (QPI) — driving data-driven improvements.

Definitely. Evaluate suppliers based on inspection outcomes, incorporating their performance into supplier dashboards to optimize procurement decisions.